- About

-

Services

-

Audit, monitoring, consulting of fire safety systems

-

Design and creation of fire safety systems

-

Installation of automatic fire fighting systems

-

Connection to a centralized server to maintain day and night monitoring.

-

Fire protection of constructions and buildings.

-

Fire alarm

-

Installation of fire hydrants and water pipes

-

Smoke removal and ventilation system

-

Automatic gas fire extinguishing system

-

Extinguishing the fire with dispersed water

-

The use of robots in the fire fighting

-

CCTV systems

-

- Products

- Projects

- Blog

- Partners

- Contact us

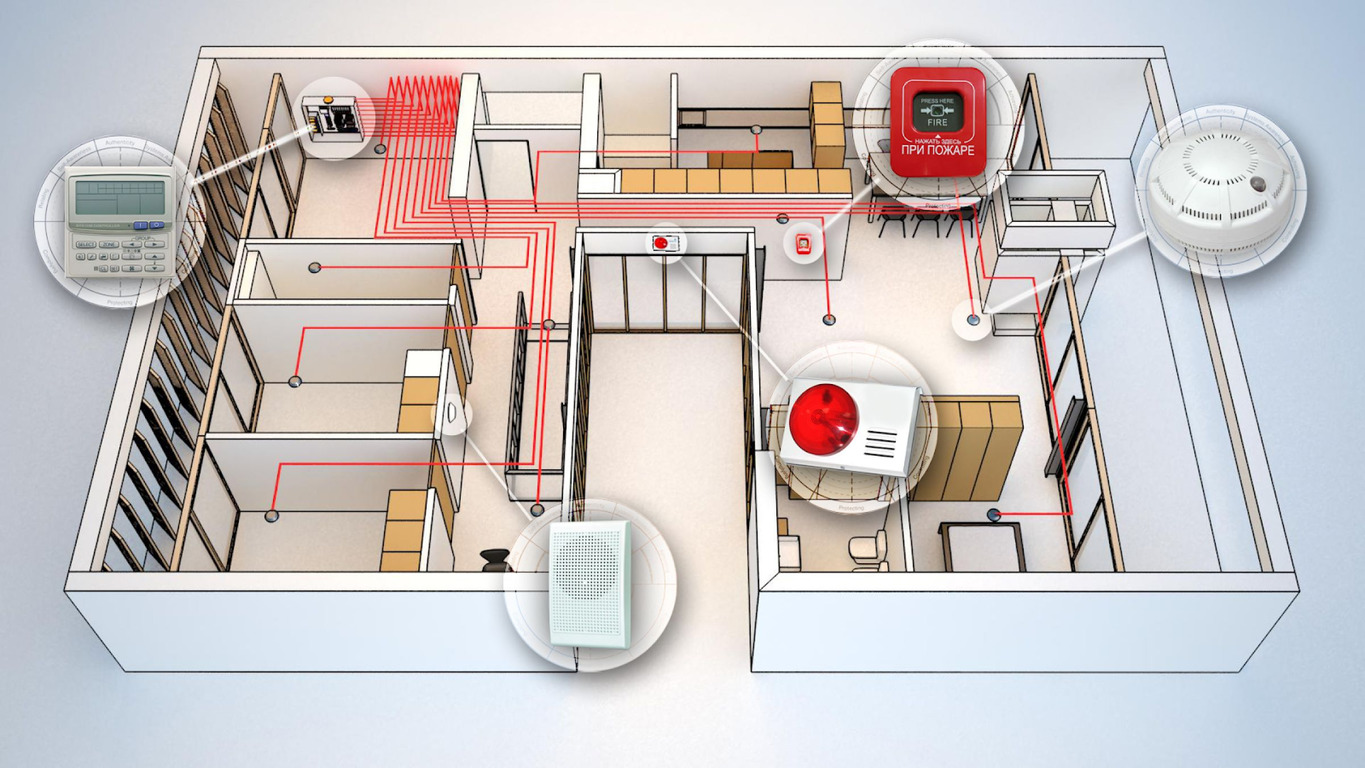

Installation of automatic fire fighting systems

Installation of automatic fire fighting systems

All automatic fire extinguishing systems (AFES) is primarily divided into local and centralized systems. After that ASPT classified as sprinkler and drencher, depending on mode of operation. And according to the method firefighting differ by physical properties and chemical composition of fire extinguishing mixture.

Within each AFES should be a warning device that responds to smoke, an increase in temperature and other signs of fire; set recording, preparing and transmitting control signals and the executive body directly performing firefighting. In the local system, all this combined in a single unit that can be transported, installed and maintained in a single form. The most simple and reliable local system is baloon with extinguishing mixture.

In this balloon there is persistently high pressure, which can be broken by chemical reactions triggered by depressurization or by applying a control pulse. In this system, the role of the closing valve is played by sprikler itself. Within these sprinklers there is a rapidly melting element which operates at a temperature of 40oC - 150oC, depending on the maximum temperature that can be achieved within rooms without fire. Typically, these blocks are attached to the fire alarm system only as a warning device. In principle, these units can operate without any wires or electricity. The disadvantages of these systems are their relatively high cost and weight, complexity of their service and the inability to analyze more specifically the situation for activation.

Using centralized AFES on large objects is more justified from an economic point of view. In these systems, it is possible to use a large number of alarm devices and logical units, responding to a fire in time with 100% guarantee and eliminating false starts. But along with this, the use of such systems requires the presence of electric power in all the rooms and alarm sensors, and most importantly - high-pressure lines. If the room is small or separated by partitions that prevent the spread of fire, then it is more appropriate to use the individual sprinklers. These sprinklers, when running, will start extinguishing mixture directly on the point of ignition. When the pressure in the pipeline is down main control valve starts pumping providing mixture to the sprinklers. Main control valve also responds to the pressure drop in the line at sites where there is a risk of pipes’ freezing, but there is not always liquid in the line.

Over large areas and rooms where there is a favorable environment for the spread of fire is required, and even more preferably, putting out the fire on the perimeter. In such cases, a drencher system is used. In the drencher system, there is no need for valve in each dispenser or in maintaining a constant pressure in the line, because the fire extinguishing mixture is fed into the system only by the signal of control device or after manual launch by responsible officer.

Our company provides designing and installation of all systems, taking into account the features of the object and purpose, technical and economic assessments. We are ready to provide services for post-warranty maintenance, service and routine maintenance of any system, as well as to enter into contracts for the work done by.